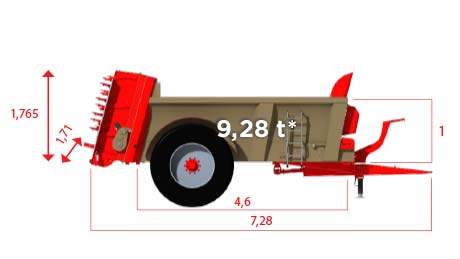

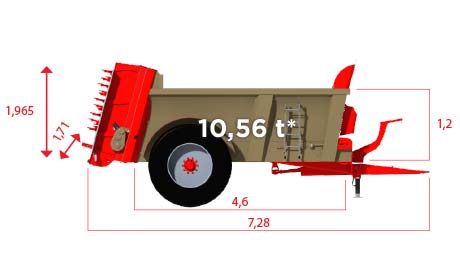

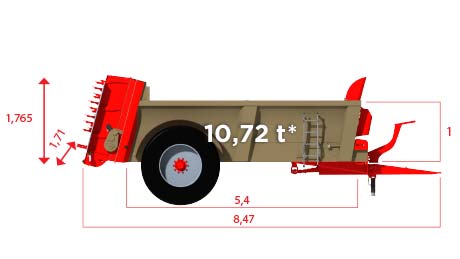

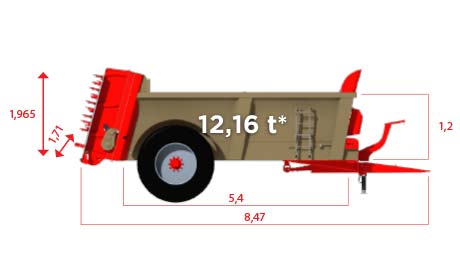

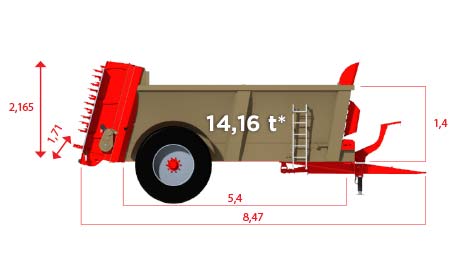

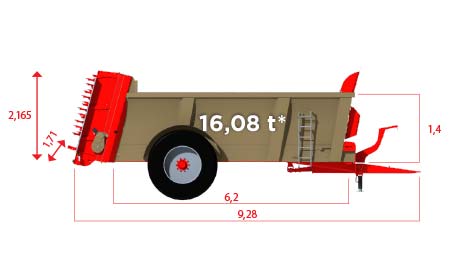

- Single or double axle, from 10.7 to 24.3 m³.

- Designed to withstand the toughest working conditions over time

Rounded body

Rounded body to facilitate the unloading of goods, made by bending the sheet metal for an increased rigidity of the side walls.

Design

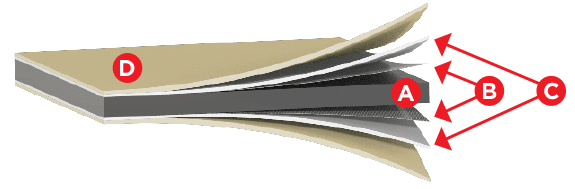

Protection with 2-component paint (2K industrial quality)

(A) Body in ST420 high tensile steel sheet (thickness: 4 mm).

(B) Shot blasting.

(C) 2K primer coat applied directly after blasting + flash-off before applying the finish.

(D) Finish with 2K paint and a hammered effect.

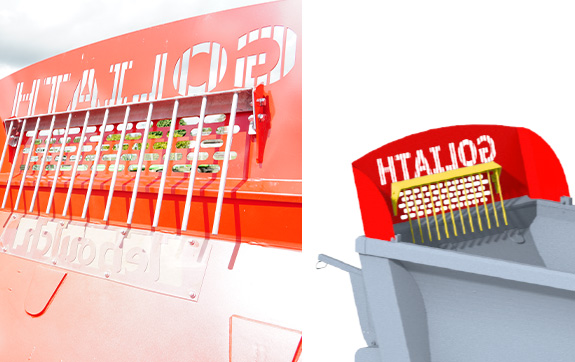

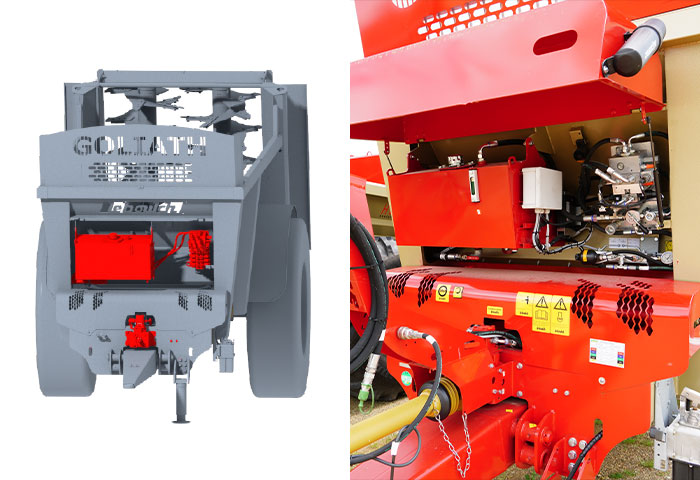

Headboard with self-cleaning grate.

TECHNICAL POINTS

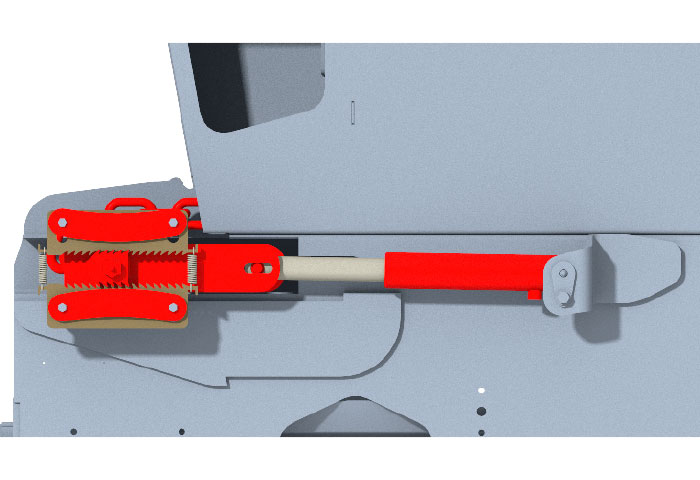

Hydraulic moving floor tensioner with automatic tensioning safety device.

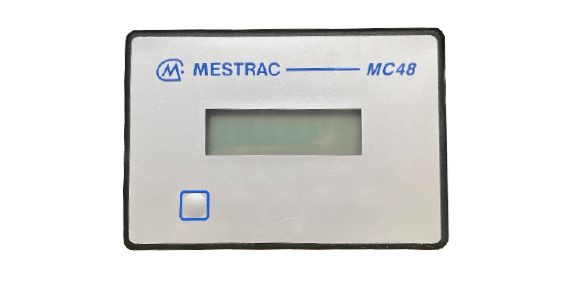

Control box

DPA (proportional flow): automatic regulation of the moving floor speed according to the door opening (except FERTI 500) and driving speed. Control box to be placed in the tractor.

(A) Simplified DPA (FERTI 500 control box)

(B) Precision DPA (FERTI 4000 control box)

Digital work counter

Management

Hydraulic installation with electric control, 140 l tank and electrohydraulic system protected under the hood.

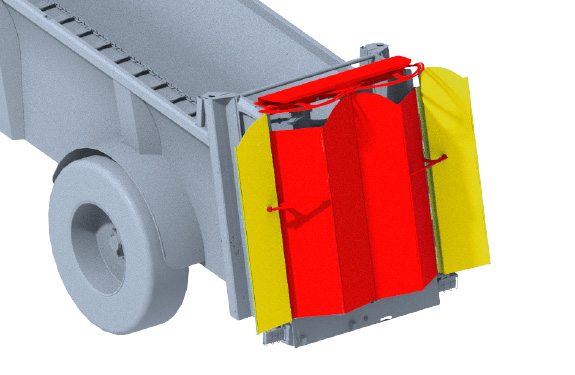

Spreading system

Crossing widths (variable according to the material spread):

(A) 8 m (standard)

(B) 9 m with spoon knives

(C) 10 m with spreading discs

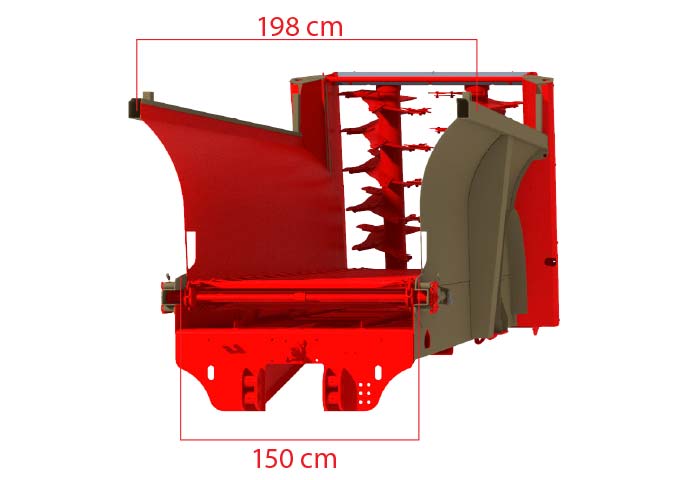

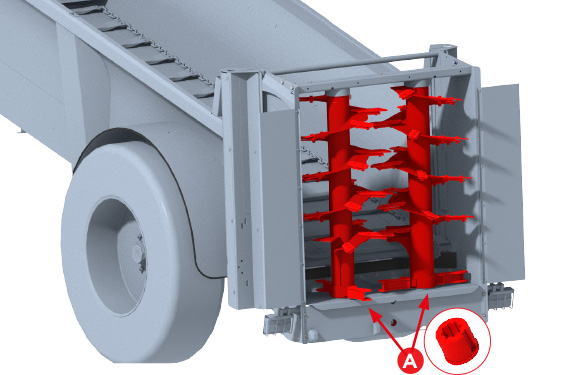

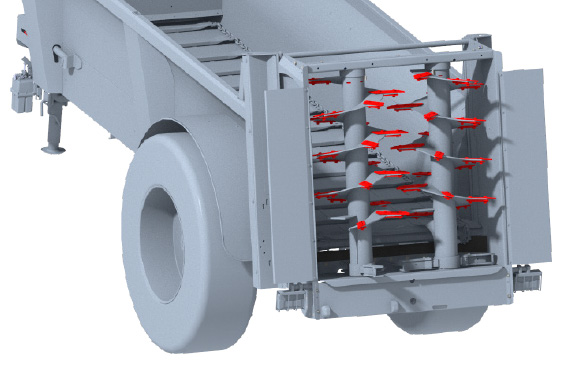

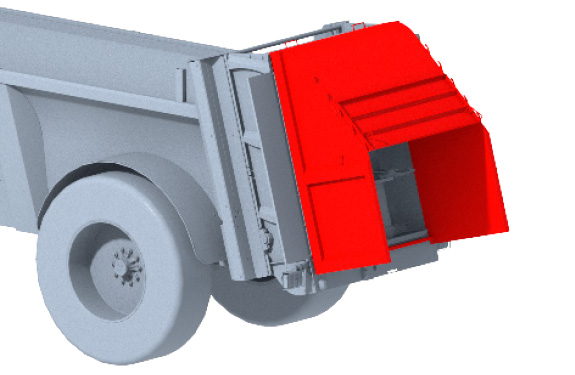

Beaters

Ø 900 mm beaters and 10 mm spirals Beaters with centralised lubrication. Galvanised deflectors with sharp edges for cutting string.

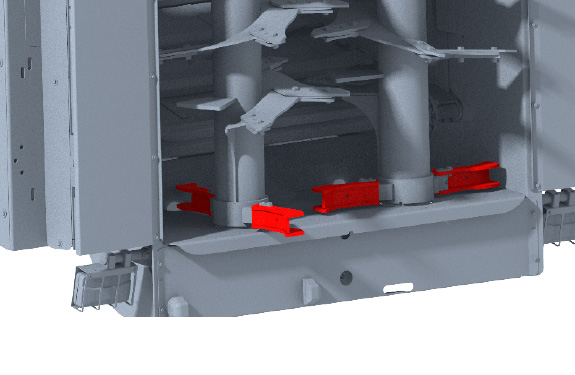

(A) Wear ring under the beaters.

Removable blades on wear ring for improved crumbling.

Reversible interchangeable blades in HARDOX 450

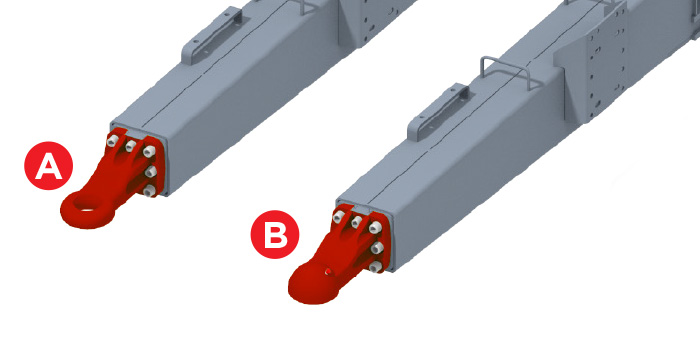

Eyelets

Choice of eyelets

(A) Bolted Ø 50 mm (standard)

(B) Bolted knee-joint (option)

Canopy

Safety protection for on the road

Composting canopy

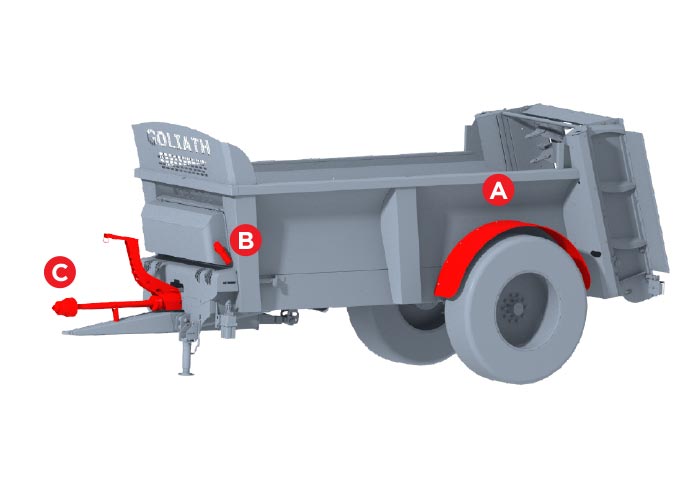

Mudguards

(A) Steel mudguards

(B) Document tube with individualised spare parts book

(C) Hose holder and wide-angle P.T.O.-shaft with cam security.

TYRES

Videos

Documentation

Documentation  Shop

Shop  Leboulch group

Leboulch group  News

News  Historical summary

Historical summary  Jobs

Jobs  Agenda

Agenda  Discover the Leboulch manufacturing process

Discover the Leboulch manufacturing process